Operational update on development program

ASA, the developer of a proprietary Fischer-Tropsch technology that converts synthetic gas into fuel including sustainable aviation fuel (“SAF”) is pleased to provide an update

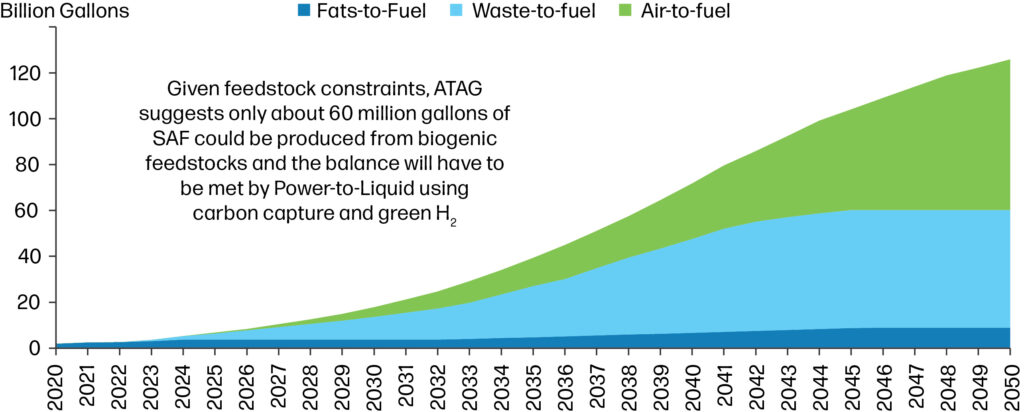

120 billion gallons of sustainable aviation fuel will be required by 2050 for the sector to reach Net Zero. This is a significant target market for ASA’s Fischer- Tropsch reactive technology.

120 billion gallons of sustainable aviation fuel will be required by 2050 for the sector to reach Net Zero. This is a significant target market for ASA’s Fischer- Tropsch reactive distillation column

Produced from biomass, municipal waste, green power, industrial processes and natural gas

Utilising ASA’s proprietary reactive distillation technology

Sustainable aviation fuel, diesel and gasoline

ASA is at the forefront of developing proprietary technology to convert a range of synthetic gas (hydrogen and carbon monoxide) into net-zero sustainable aviation fuel (“SAF”) and other renewable petroleum products.

This synthetic gas can be sourced from municipal waste, biomass, flared natural gas and industrial waste gas.

In time, ASA expects to also convert ‘green’ synthetic gas (hydrogen produced via electrolysis and carbon monoxide from captured carbon dioxide) into fuel products via its reactive distillation column (“Air to Fuel”).

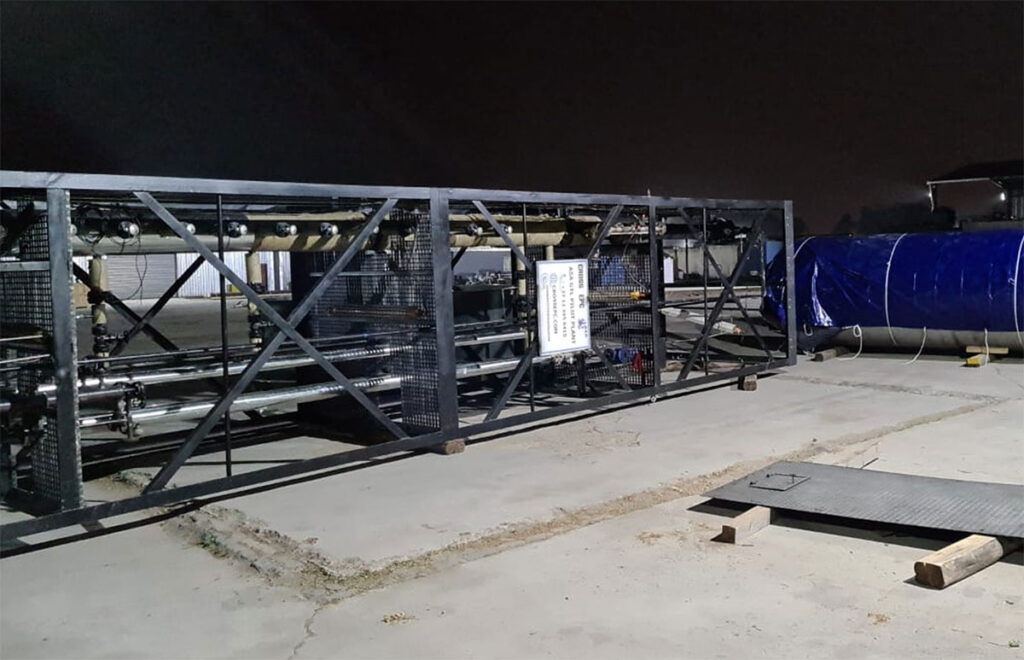

ASA’s reactive distillation technology has been tested in South Africa and a unit has now been transported to the UK for testing downstream of a municipal waste gasification process. The target is to produce modular waste to SAF facilities (“Waste to Fuel”) that can be integrated or located close to the sources of waste from the end of 2024.

ASA’s reactive distillation column in transit to the UK for testing downstream of a waste gasification process.

The conversion of these gases to SAF will be required for the aviation sector to achieve net-zero emissions by 2050. In 2019, aviation consumed nearly 100 billion gallons of jet fuel (~8% of global oil demand). This is expected to increase to ~175 billion gallons by 2050 of which 65% or ~ 120 billion gallons is expected to be SAF.

“Simply put, there is no realistic option that could replace liquid fuels in the commercial aircraft fleet in the coming decades. Even with significant investments in electrified aircraft propulsion technology and/or cryogenic hydrogen powered aircraft, it will take many years for technology to mature to the point of adoption, leaving the aviation industry dependent upon liquid hydrocarbon fuels for the foreseeable future. While there may be a role for hydrogen on shorter-range flights and more broadly in the years beyond 2050, we do not expect hydrogen-powered aircraft to make a significant contribution toward achieving net zero aviation emissions by 2050.”

Federal Aviation Administration (FAA): United States 2021 Aviation Climate Action Plan, November, 2021

“We estimate that SAF could contribute around 65% of the reduction in emissions needed by aviation to reach net-zero in 2050. This will require a massive increase in production in order to meet demand. The largest acceleration is expected in the 2030s as policy support becomes global, SAF becomes competitive with fossil kerosene, and credible offsets become scarcer.”

International Air Transport Association (IATA), Net Zero 2050: Sustainable Aviation Fuels

ASA has also constructed and tested a steam methane reformer that can convert natural gas into synthetic gas. This both enables ASA to produce blue and grey hydrogen as well as converting natural gas into synthetic crude. The overall facility is compact and may be integrated within upstream facilities allowing for the resulting synthetic crude to be combined with the crude oil before shipment.

Simultaneous to the development of modular waste to fuel facilities, ASA will construct and integrate ASA’s technology within operations that are emitting significant amounts of carbon dioxide namely a blast furnace and an upstream oil operation that is flaring natural gas.

Source: Air Transportation Action Group (ATAG) and Barclays Research

© 2022 ASA Energy Ltd

ASA, the developer of a proprietary Fischer-Tropsch technology that converts synthetic gas into fuel including sustainable aviation fuel (“SAF”) is pleased to provide an update